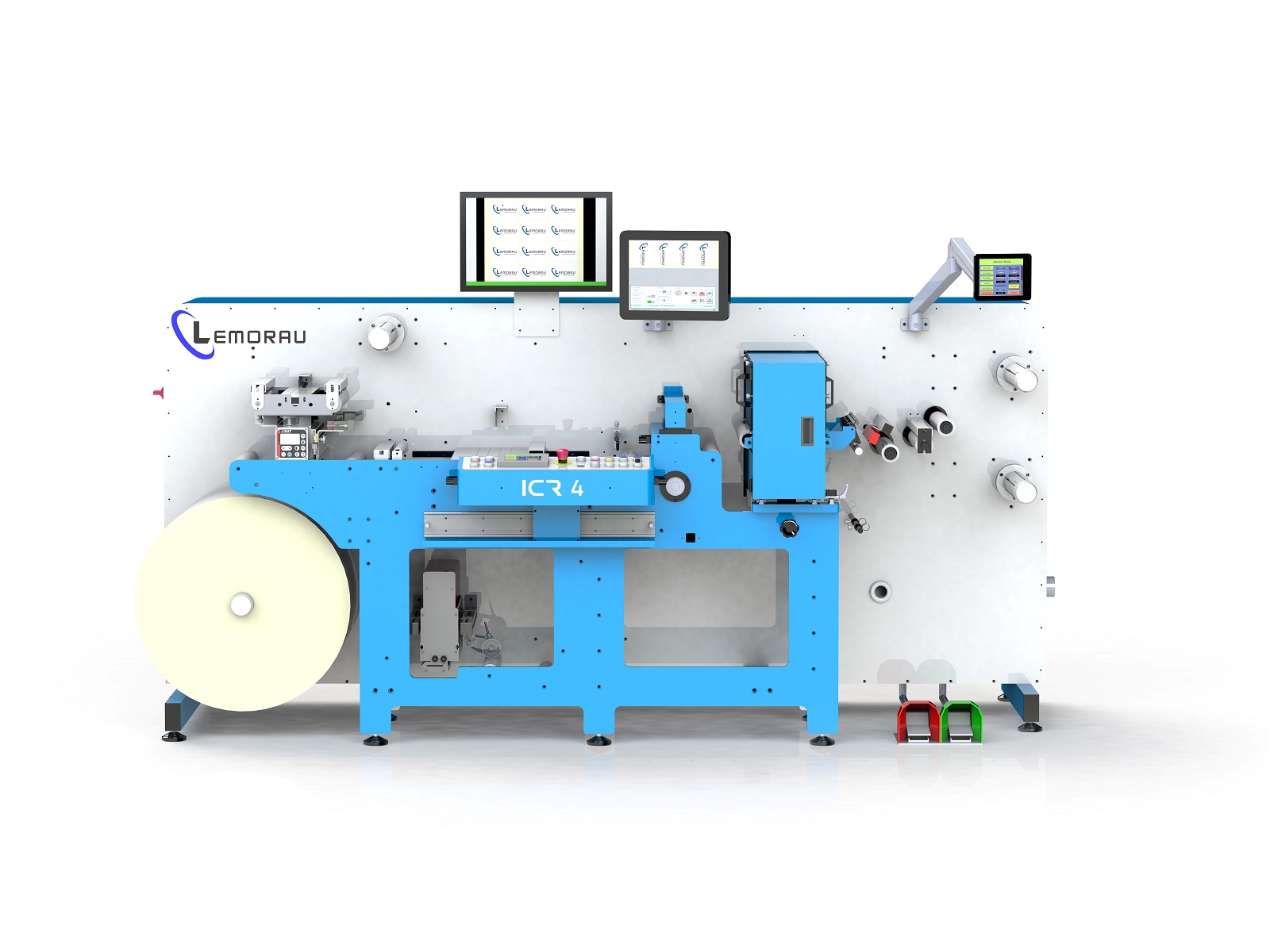

LEMORAU ICR4

High speed inspection machine

Lemorau ICR4 is developed for an exceptional fast finish. It slits and rewinds at 400m/min. and it can run up to 295 m/min. with the optional of video inspection.

For a fast set up, ICR 4 is equipped with an automatic positioning of slitting knives and a job memory functionality for quick job changes. Web tension is controlled by servo motors and totally independent on each shaft.

With the latest and very user-friendly software, makes ICR 4 very practical and easy to use.

- Max speed slitting and rewinding 400 m/min

- Max speed inspection 295 m/min

- Web width 350 mm (14”)

- Electronic Counter (labels / meters / rolls / total meters and labels / diameter)

- 250 Job memory for easy and quick job set ups

- Paper break detection

- QRC (Quick Remote Connection) diagnostic system

- Automatic web tension control system by servo motors – Constant and Taper tension

- Multi language HMI touch screen

- Air trim removal

- Reverse jog

UNWINDER

- Servo driven unwinder with max. Ø 700 mm (27,5”)

- Pneumatic shaft Ø 76mm (3”)

- Electronic web guide system

- Adjustable splice table with pneumatic clamps

- Flag detection sensor

- Automatic stop at master roll end with programmable end of roll function

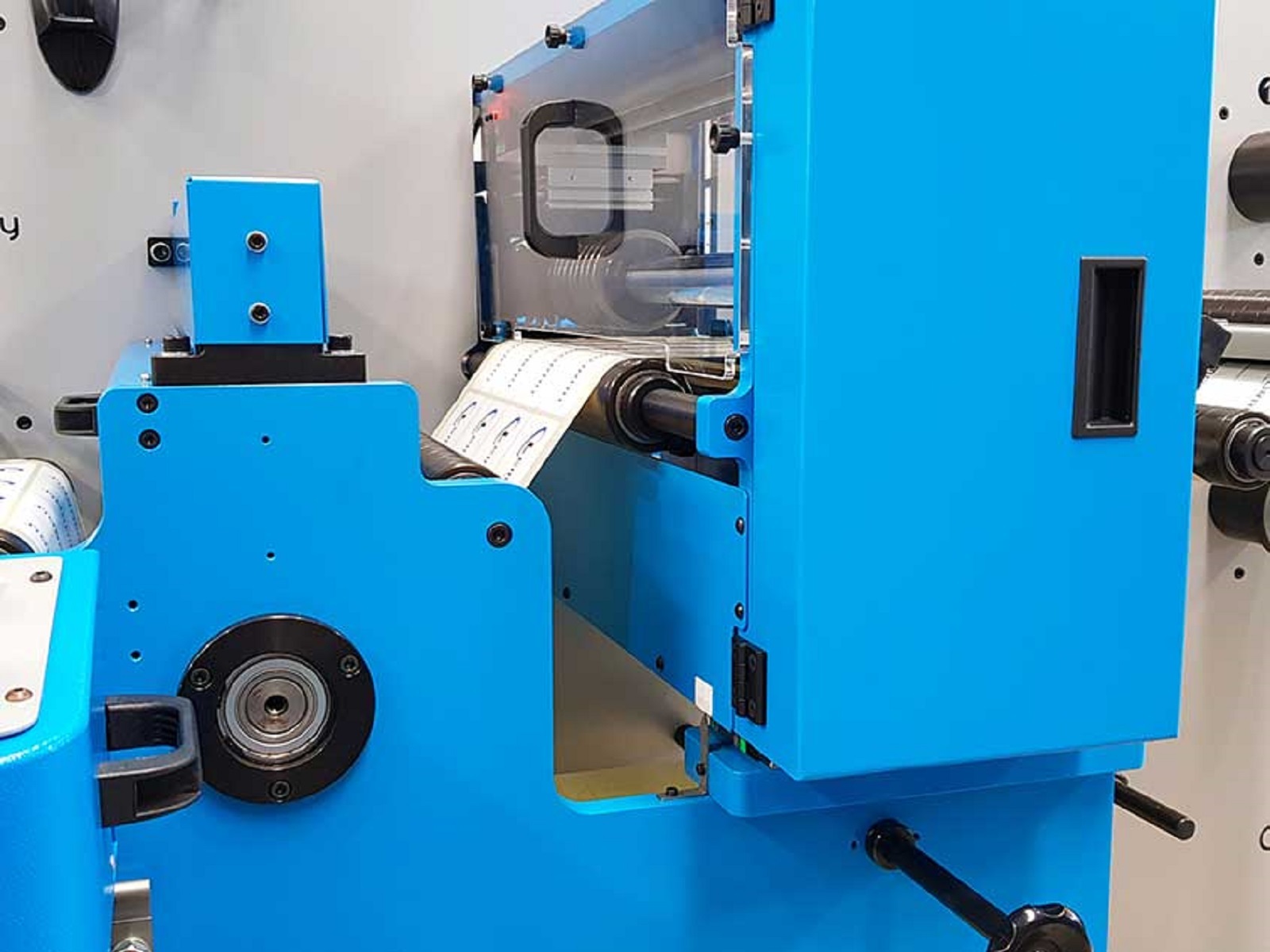

INSPECTION

- BST / E+L 100% inspection systems as option

- Adjustable splice table with pneumatic clamps

SLITTING

- Set of 6 circular knives with automatic positioning

- Extra knives available as option

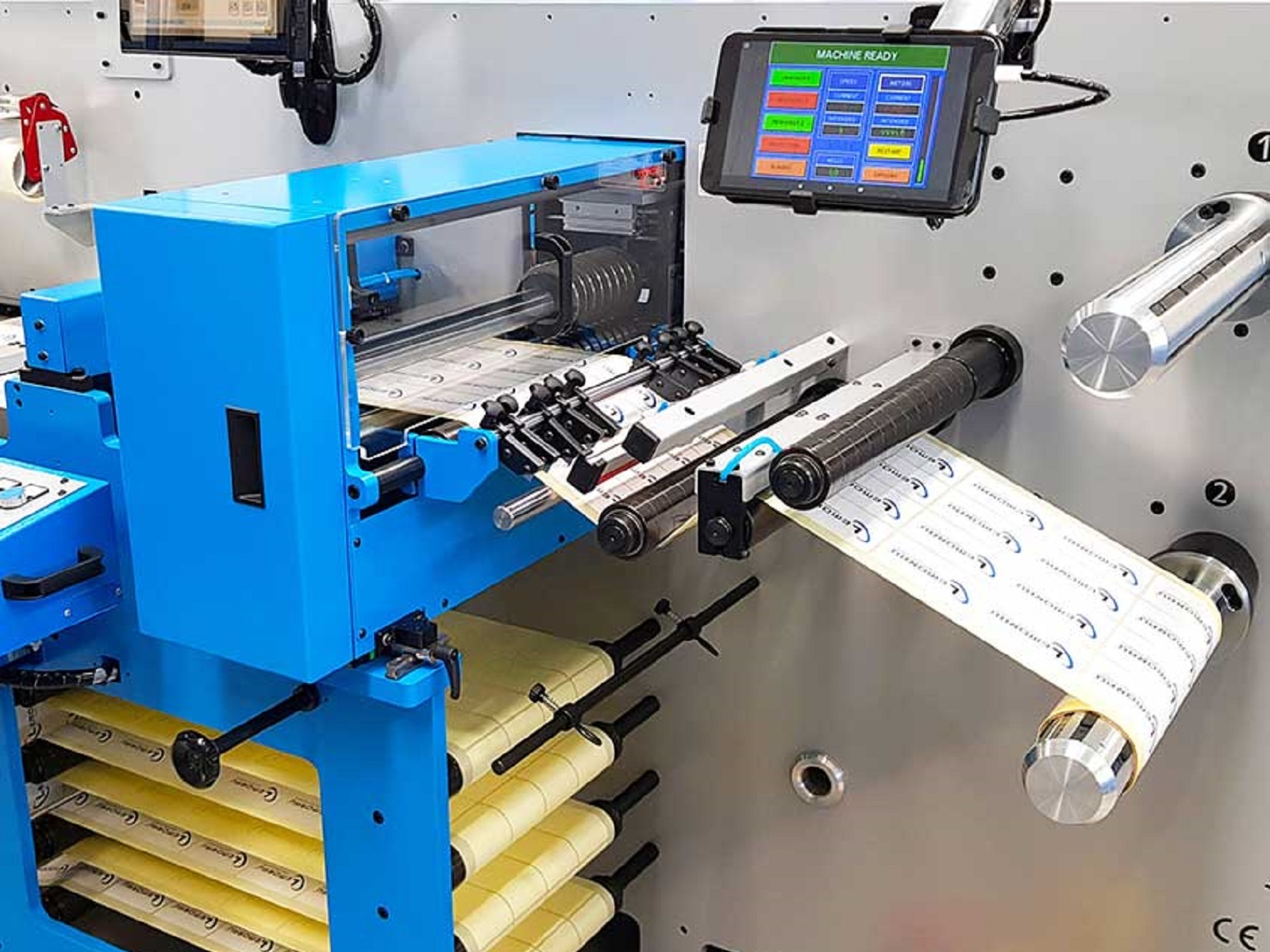

REWINDING

- Two servo driven rewinders with max. Ø 500 mm using single rewinder / 350 mm using two rewinders

- Pneumatic shaft Ø 76mm (3”)

- Labels in/ labels out rewinding

- Anti-static bar

- Waste rewinder unit

- Additional slitting knives

- Razor slitting knives

- Rewinder unit for defects

- Additional mandrels in customized sizes

- Clear on clear sensors

- Industry 4.0 kit

Contact us for info