Mida MD280 semirotary label press, year 2010, with:

- Unwinder with automatic roll lifter, Ø 3" pneumatic shaft and splicing table with pneumatic brackets.

- Vacuum suction system for high-speed guiding of synthetic media

- Infeed panel with teflon anti-adhesive guides and electronic noise reduction system.

- 5 letterpress shaftless printing modules with automatic washing system, ink keading system and ink fountain roller with electronic speed adjustment according to machine speed, pneumatic anti-ghosting inking rollers.

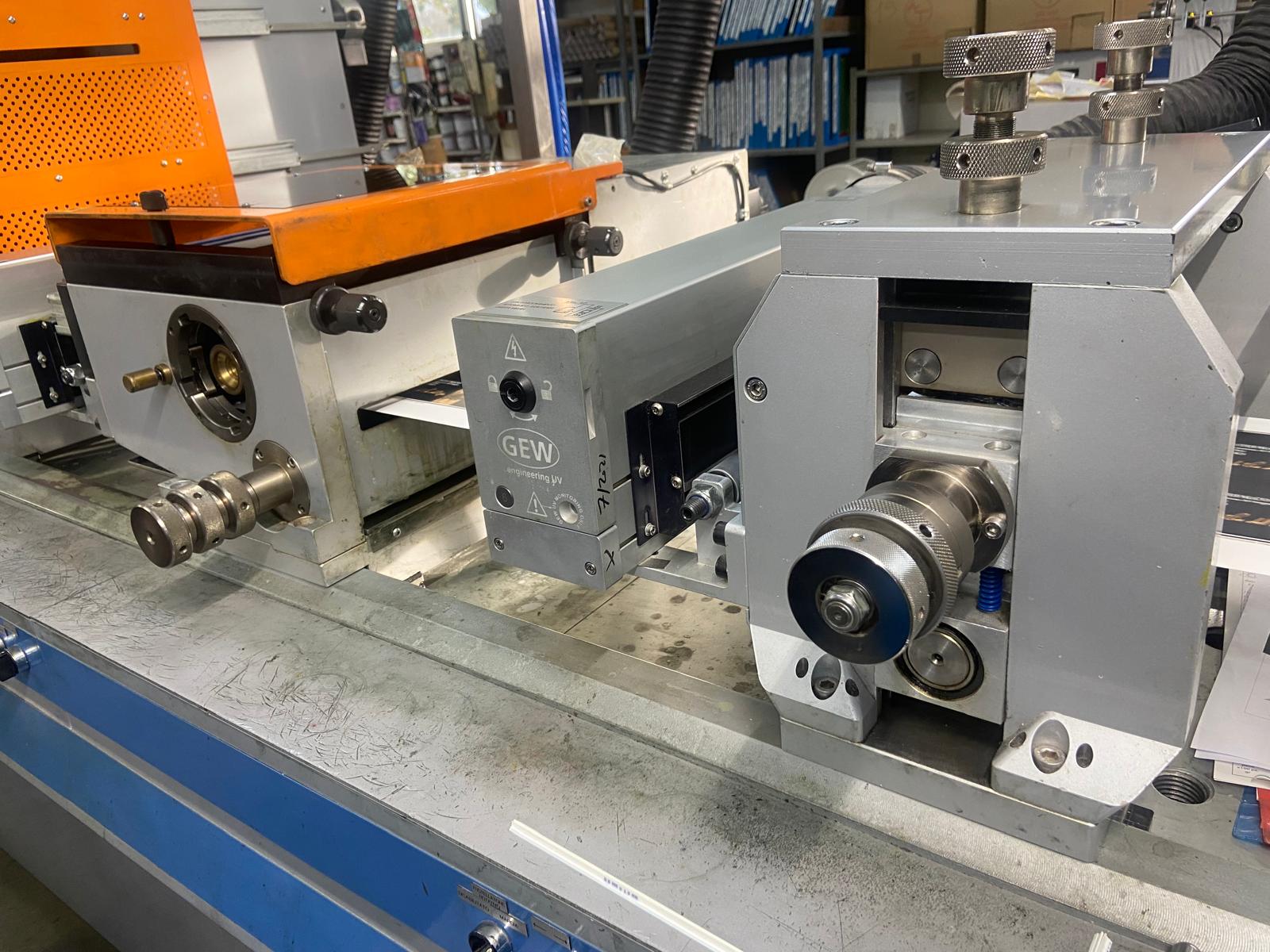

- Tresu Flexiprint shaftless flexo printing unit, with closed doctor blade chamber, anilox roller, auto engagement at machine start/stop, quick extraction system for anilox roller and doctor blade.

- 6 Gew UV lamp drying modules, with automatic power adjustment according to machine speed.

- Water cooling system for Gew UV system, consisting of cooled plates and MTA Tae Evo chiller.

- Semi-rotary shaftless die cutting unit, with K+B GapMaster pressure system.

- Electronic pre-register system, with automatic longitudinal positioning of the printing and finishing modules.

- Syncrotech electronic system for automatic maintenance of print register during acceleration, deceleration and machine stop&go. With this system, it is possible to start work at very low speeds, then accelerate to the desired production speed, decelerate, stop or restart work, keeping the register within the set parameters. Automatic speed variations can be programmed from the machine's HMI, depending on the number of labels and the number of reels to be produced.

- BST ‘Powerscope 4000’ video inspection system with split screen function.

- Remote diagnostic system.

- Sensors for ‘clear on clear’ media.

- HMI with 15" colour LCD display, keyboard and mouse, with data job memory.

- Bob 350 slitter / rewinder with two pneumatic rewinding shafts.

- 6 "quick lock" magnetic plate sleeves.

- 2 "quick lock" steel plate sleeves for flexo unit.

Semi-rotary technology is ideal for newcomers in professional label production. Printing and finishing can be performed in a single pass. Job changes are performed in minutes, with little media waste, without the need to change the size of printing or die-cutting cylinders. The main adjustments are managed digitally.

The machine is in excellent condition and can be viewed and tested at current owner's premises (Italy). Negotiations and sale will be handled directly with the current owner.

Price €75,000.00 + VAT, negotiable. Subject to prior sale.