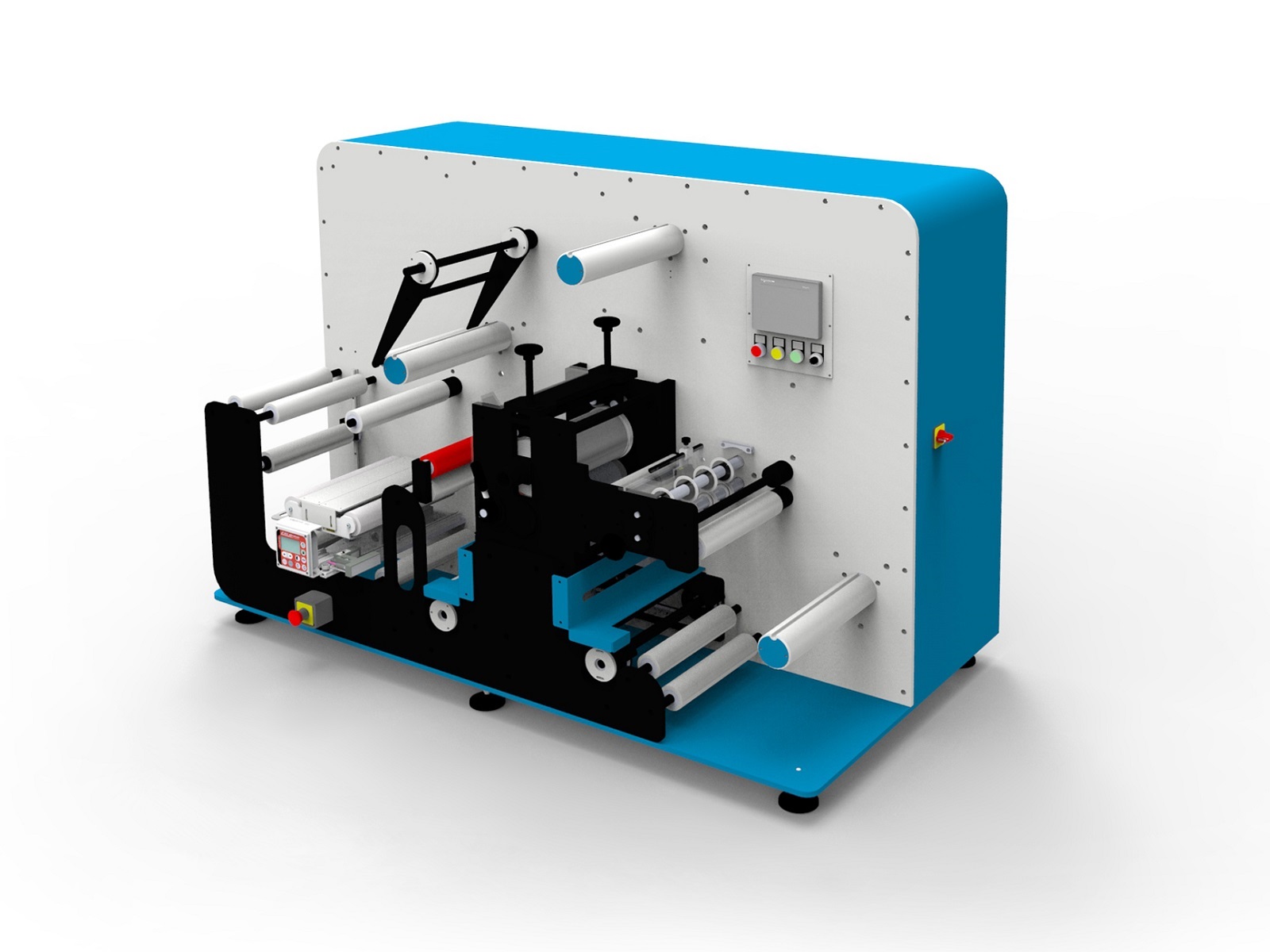

LEMORAU EBRM+

Compact label finishing machine

Lemorau EBRM+ is a table top finishing machine, cost effective and simple to use. It can be used inline or offline with digital or analogic printing sections.

Its compact size and short web path allows to minimize set up waste. Lemorau EBM is capable of laminating, die cutting, slitting and rewinding labels with maximum speed up to 80 m/min in rotary mode or 25 m/min in semirotary mode.

- Max speed (rotary die cutting with register): 80 m/min

- Max speed (semirotary die cutting with register): 25 m/min depending on job

- Web width 250, 330 mm (10, 13″)

- Electronic counter (labels / meters)

- 250 Job memory for easy and quick job set ups

- Integrated buffer for use inline with analogic or digital printers (needs web tension), with sensors to start, stop, move faster and move slower depending on web feeding

- QRC (Quick Remote Connection) diagnostic system

- Multi language HMI touch screen

UNWINDER

- Unwinder with max. Ø 450 mm (18”)

- Mechanical shaft Ø 76mm (3”)

- Clockwise / counterclockwise unwinding

- Splice table

- Electronic web guide system

LAMINATION

- Linerless lamination unwinder Ø max 450 mm. (18”)

- Mechanical shaft Ø 76 mm (3”)

DIE CUTTING

- Operates in full rotary or semirotary mode

- Die repeats in rotary mode: min. 203,20 - max. 412,75 mm (8 – 16,25″)

- Standard gears for magnetic cylinders are 1/8 CP, straight teeth, angle 20 degrees

- Recommended die repeat in semirotary mode (Z130): 82,55 – 330,20 mm

- Servo driven buffer for semirotary web movement

- Servo driven waste rewinder max. Ø 450 mm (18”)

SLITTING

- Set of 3 circular knives with lateral adjustment – Can be added more as optional

- Razor knives unit – as optional

REWINDING

- Rewinder with max. Ø 450 mm (18”)

- Mechanical shaft Ø 76mm (3”) – other as optional (min Ø 40 mm)

- Clockwise / counterclockwise rewinding (labels in / labels out)

- Additional circular knives

- Pneumatic shafts (with auto inflate/deflate function)

- Clear on clear sensor

- Infeed panel for use inline with screen or semirotary machines

- Industry 4.0 kit

Contact us for info